Comprehensive Aluminium Services

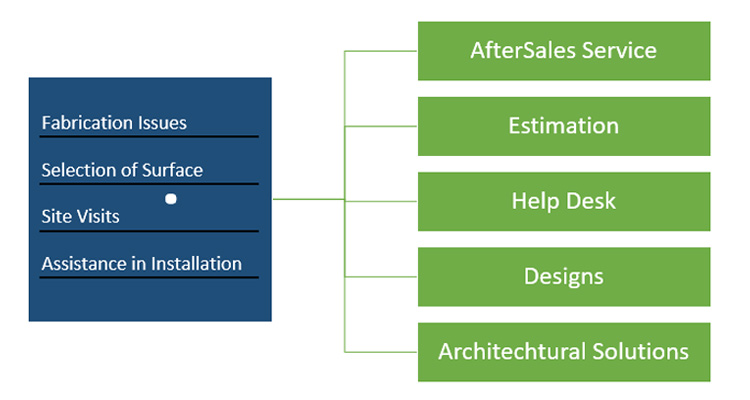

Providing advice on aluminium fabrication work is an essential aspect of the service-centered approach of our business. This also includes advice on architectural solutions, installation assistance, and exceptional after-sales service.

Door Windows Curtain Walls Designs

At Alumex, providing top-tier customer service is of highest priority; and the key factor behind our ability to achieve a consistently high customer retention rate over the last three decades.

Alumex strives to provide an ongoing support system for our customers, including -but not limited to-: pre-sales and post-sales support, technical assistance, shop drawings based on customer drawings/sketches, site visits irrespective of project location, and all other necessary support required in the selection of suitable fabricators. Alumex provides the same level of service irrespective of project size, be it an individual, government body, or large-scale contractor, fabricator, or even end-user. Our marketing and technical teams are trained to be supportive to all customers who approach us with interest in our products.

Our design team is proficient in designing solutions to suit individual requirements. As an additional service to our customers, we undertake drawings of doors, windows, curtain walls, etc., as well as the verification of customer drawings -making counter drawings according to the specifications of Alumex aluminium profiles. Our qualified and experienced team is happy to offer their expertise to benefit our valuable customers.

Customer feedback for our products are generously accepted, always resulting in prompt action. Furthermore, aluminium as a green product doesn’t have a negative impact on the environment nor on the end users, and our design team is constantly working to further implement new processes that will deliver safe products to customers.

AluSys Software System

A modern software system, AluSys was introduced to the market in 2019, with the aim of helping customers accurately design solutions with the appropriate profiles, quantities, and to the right estimates. A retail customer who visits the Lumin center can obtain this service free of charge. However, many customers have chosen to purchase the AluSys software for themselves, acknowledging the value of the software as well as the convenience it provides for all aluminium-related projects.

Alumex Training School

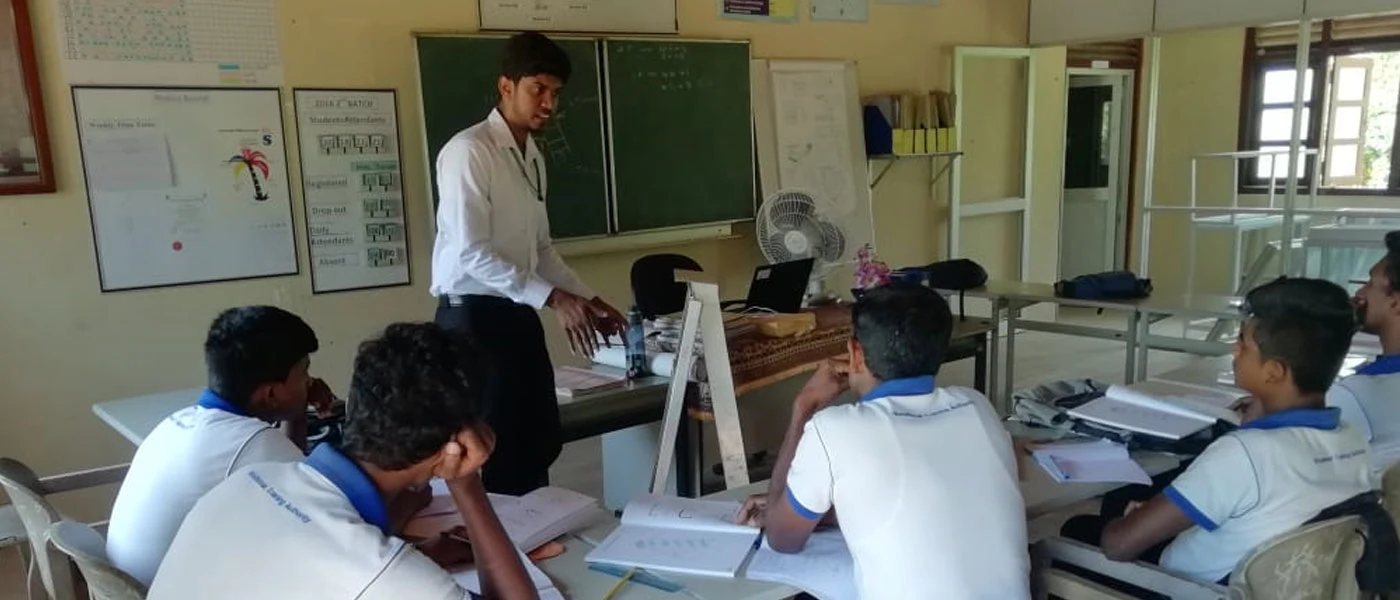

Our training school conducts both in-house and offsite fabricator training courses free of charge in order to educate and propagate the use of aluminium extrusions in building construction. Training is undertaken by our well-experienced staff who are conversant with the industry requirements and standards. Our aim is to uplift the skills of the apprentices, fabricators and consultants in the building construction industry in modern methodology and to educate them in the usage of appropriate equipment, accessories, etc. so as to supply durable products to the customers.

Alumex always take extra efforts to expand our market reach by conducting fabricator training and awareness programmes. Alumex undertakes extensive training each year to increase awareness about our products and processes to end users and decision makers, including fabricators and technocrats.

Alumex training centre has become an asset, not only for Alumex, but for the country as a whole. The fabricator training centre which was established in 1998 has supported the development of the community immensely for the past 21 years. This state-of-the-art training center has been established at the Alumex factory premises in Sapugaskanda to train fabricators and technocrats. This training school has become an alma mater for most of the fabricators, technocrats, trainers of the training centers as well as many government officers. Some of the programmes conducted by the training school can be classified as below.

Technical Colleges

In order to develop educational capacities and self-employment opportunity for school leavers, Alumex has engaged with the Government Technical Colleges island-wide and provided them course materials to develop skilled fabrication technicians while improving quality of life. In addition to this, we contribute towards knowledge and skill improvements of lecturers at Government Technical Colleges

Dealers & Fabricators Training

In order to ensure that the dealers and fabricators are competent in handling Aluminium profiles, particularly new Aluminium -based systems, Alumex conducts advanced system design introduction programmes, for fabricators of the Alumex dealers. Practical training is conducted island wide with dealer collaboration. Professional and Private Institutions Central Engineering Consultancy Bureau and the Department of Buildings are some institutes that were trained by Alumex during the financial year. Alumex conducts external and in-house training programmes for professionals in new advanced systems and related fabrication techniques with the support of new, high quality accessories. These programmes aim to educate construction industry professionals on the many different applications of Aluminium profiles and quality differences compared to competitor and substitute products.

VTA Training

Alumex has partnered with the Vocational Training Authority (VTA) to provide training in Aluminium fabrication. The scope of training activity includes train the trainer programmes, lectures and practical trainings for trainees, supervision of VTA training centres and providing course materials.

Government Institutions

Colombo municipal council, Government factory authority, CIDA, National Institute of Education, Industrial Development Board, SL Army, SL Navy, Technical colleges are some of the institutions that have been benefitted by the Alumex training school during the financial year under review. We contribute towards knowledge and skill development of technical staff of Government Institutions that make a substantial contribution to the Sri Lankan construction industry. Alumex conducts in-house and external training programmes on proper use of Aluminium profiles for window, door and façade systems fabrication.

NVQ Certification

We arranged the training centre free of charge on behalf of training institutes that have no resources to conduct exams and assess students for such certificates. Alumex facilitates skilled fabrication technician’s applicants to obtain NVQ certification by facilitating their fabricating skills. Fabricators and all testing materials associated with the assessments are provided by Alumex free of charge. obtain NVQ certification. Therefore, the free of charge facilities provided by Alumex to was used to conduct three programs to assess technicians. All programs mentioned above are conducted by well-trained Company staff. During the programme, Alumex provides training materials, courses materials, meals and refreshments to participants, in addition to free training. After completion of training, Alumex issues a certificate which is recognized by Sri Lanka’s engineering community. Over the past few years, we have trained more than 18,000 fabricators and technocrats.

Customer Die Design

Driven by energy-efficiency and the willingness to take responsibility for our planet and future generations, we forge ahead, ensuring that our innovations do not leave behind a tangible negative impact on the environment. In keeping pace with modern designs, preferences, and evolving trends in the construction industry, our focus is always centered on introducing revolutionary products to our customers. Alumex-owned and tested systems were launched under the brand “Alumex TS”, and together with the “AluSys” design calculation software system, we are able to offer a wide variety of options and greater ease to our customers. AluSys helps customers accurately design solutions with the appropriate profiles, quantities, and to the right estimates. The new range of internationally accredited aluminium proprietary product ranges for domestic and commercial markets was introduced under the Alumex Building Systems (ABS) brand. The ABS range by Alumex is designed to withstand tough weather conditions, and is recommended especially for high-rise buidings – accommodating a glazing thickness up to 24 mm- comprising of unitized curtain wall systems with both structural glazing and beaded type window, door and sliding systems. Testing of the entire ABS range is carried out according to the American Society for Testing and Materials (ASTM) standards at an independent laboratory in Dubai that is United Kingdom Accreditation Services (UKAS) accredited. The tests conducted for water penetration, air infiltration, wind pressure, acoustics and safety, have all shown extremely positive results with ABS performing well above standard.

The R&D and design divisions at Alumex continuously innovate and introduce new products, work towards enhancing product quality and performance, and also conform to new and more stringent environmental and other product quality standards set by regulators; authorities such as the Institute for Construction Industry Development Authority (CIDA), the Sri Lanka Standards Institution (SLS), and other relevant international organizations. Furthermore, we engage in process improvements while introducing environmentally friendly materials and mechanisms. In order to deliver at the current pace as well as for future applications, our in-house design team is committed to developing the best and most advanced designs without compromising on quality standards and properties of aluminium. New techniques for extrusion are currently being developed that will allow for thinner walls -and subsequently less weight- while still maintaining adequate overall strength. Additionally, through innovation in component manufacturing and assembly processes, Alumex hopes to further boost the many advantages of extruded Aluminium.

Die Manufacturing

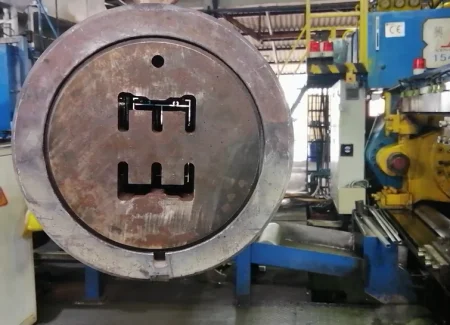

Machine including wire-cut EDM machines, as well as conventional band sawing, milling machines & heat treatment furnaces. Our highly qualified team has over 30 years’ experience in the design, manufacture and correction of extrusion dies. The experience in die manufacturing is utilized through novel designs to improve die performance in extrusion manufacturing stage.

Alumex die team has developed a new holder system with taper to spread Aluminium and eliminate the requirement Lead in Plate. New design technology reduces the friction up to die bearing by 25%. As a result of this reduction of friction the production rate can be increased by 9%. This is a significant advantage when it compared with the older technology.